Articles

Don’t forget the vital last piece

Maize silage doesn’t come together by accident. Every piece matters – hybrid selection, harvest timing, chop length, compaction and sealing. Miss one, and the system is compromised. Yet one of the most important pieces is often added last.

“By the time maize is going into the stack, most of the investment has already been made” says Shaun Body, Pioneer Brand Products Portfolio Manager. “Seed, fertiliser and harvesting costs all add up. The final step is making sure what you’ve grown is preserved”.

Once maize is harvested and ensiled, naturally occurring bacteria begin fermenting plant sugars into acids. This process determines how well energy, starch, and dry matter are preserved.

“The challenge is that fermentation without direction can be unpredictable,” Shaun explains. “If the wrong microbes dominate early on, you can lose feed value before you ever get to feed out”.

This is where a proven inoculant plays its role – helping guide fermentation toward outcomes that protect what’s already been grown.

“You don’t see silage losses at harvest – but you definitely feel them at feed-out” Shaun says.

Many of the biggest silage losses don’t occur at harvest. They occur months later, once silage is exposed to air.

“Heating at feed-out is one of the biggest sources of hidden loss in maize silage” says Shaun. “You can do everything right up to sealing, but if silage isn’t stable when air hits it, you’re still giving feed value away”.

Pioneer® brand inoculant 11C33RR is designed specifically to address this risk. It contains a proven Lactobacillus buchneri strain selected to suppress the yeasts and moulds responsible for heating and spoilage at feed out.

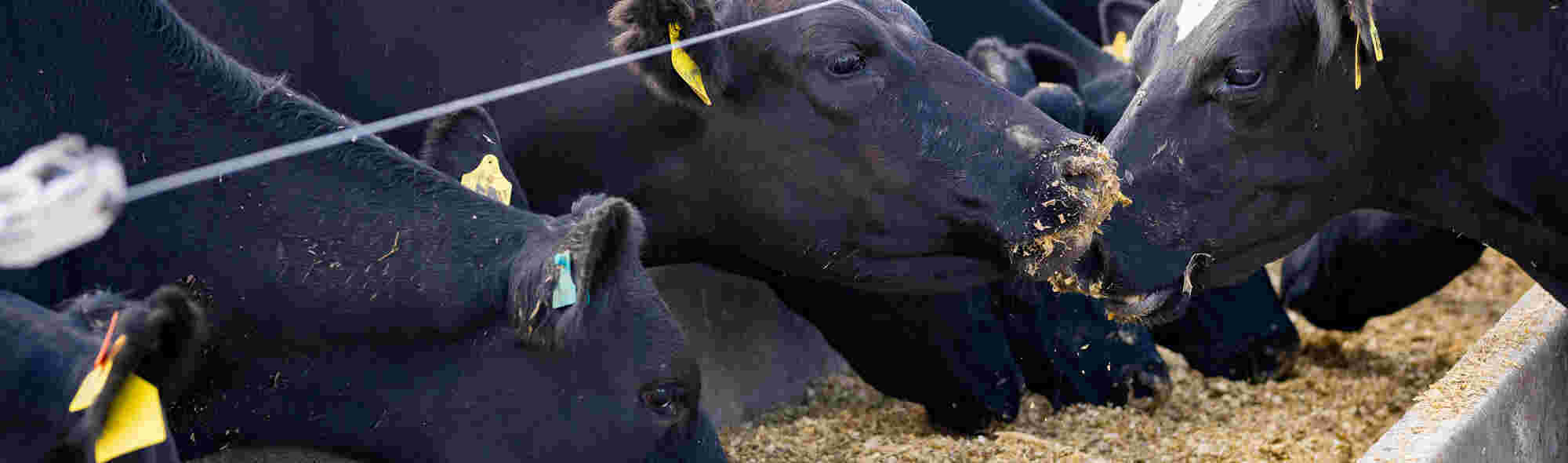

“The role of 11C33RR is simple. It helps maize silage stay cooler for longer once the stack is opened, so more of what you grew ends up in front of stock”.

Shaun says it’s a mistake to assume that all inoculants deliver the same result.

“Listing a bacterial species on a label doesn’t tell you how that product will perform. Within a species, there can be big differences between strains. That’s why strain selection and proof really matter”.

Pioneer focuses on identified strains supported by fermentation and aerobic stability research, rather than assumptions or label claims alone.

“When we talk about inoculants as the ‘vital last piece’, it’s because they complete the system” Shaun says. “They don’t replace good agronomy or harvest management – but they help protect all of it”.

For more information on Pioneer maize silage inoculants, click here or call your local Pioneer representative.